Effective Use of Steel Shot and Steel Grit for Blast Cleaning

Cleaning Process

1399/10/21

Invitation to visit Akbari Metals Melt in the 17th Metafo Exhibition

1399/11/12 Metal industries are the main users of cast sheet shot and grit. Steel mills, ferrous foundries and none ferrous foundries, workshops forging and metal fabricators. Blast cleaning with steel abrasives is an essential and critical operation in the various stages of the production of primary metals. The basic functions carried out by blast cleaning come under these categories:

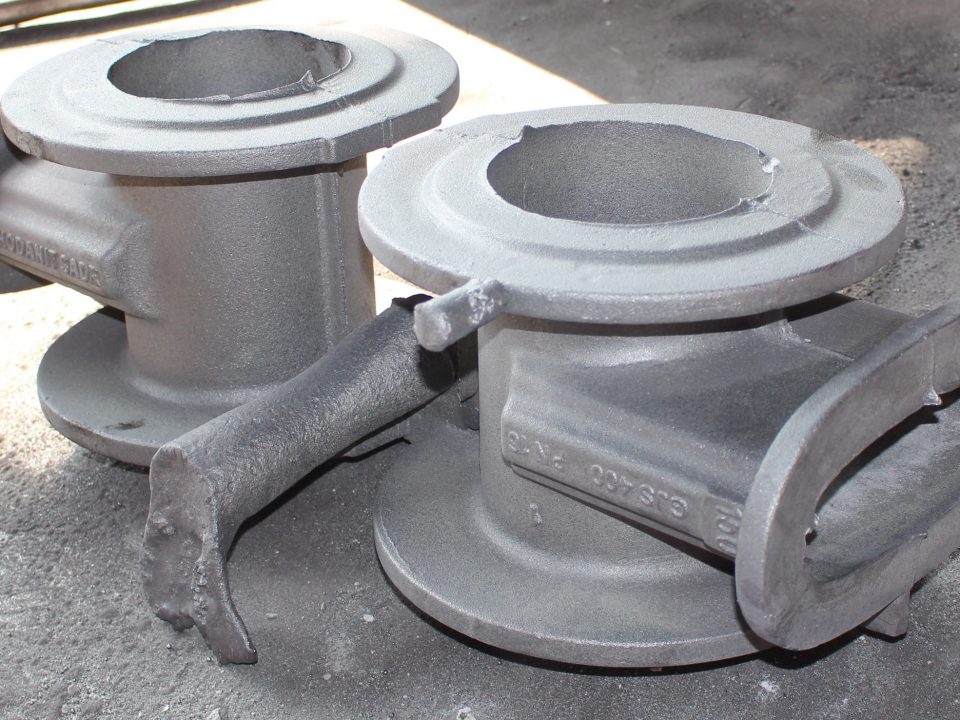

Metal industries are the main users of cast sheet shot and grit. Steel mills, ferrous foundries and none ferrous foundries, workshops forging and metal fabricators. Blast cleaning with steel abrasives is an essential and critical operation in the various stages of the production of primary metals. The basic functions carried out by blast cleaning come under these categories:➢Remove surface contamination, which provides a completely clean surface that helps to control the defects of the process.

➢Surface preparation: provide a surface profile (scratch, matte finish or anchor pattern) in preparation for subsequent processing such as painting, coating, bonding, etc.

➢The Blast cleaning with cast

steel shot

and grit can be described as an impact cleaning process in which the surface of work piece is subjected to successive bombardment by a high speed blown stream of milled abrasive particles in cast steel effective size. The effect of this blast stream impacting upon the work is twofold:

➢The contamination is broken, powdered and removed, which exposes virgin, clean metal surface.

➢At the same time, the impact force of the individual steel particles gives the surface of the clean work piece a finishing profile whose appearance and texture is determined by the user’s choice of steal abrasive size, hardness and the shape.

Mechanism of Blast Cleaning

Work properly, not just blow cleaning process will be effective in meeting the needs and user quality objectives, but also guarantee maximum productivity and lowest operating costs.

Since it is the impact force of each steel particle bearing on the double function of removing impurities and profiling, it is necessary to understand how the impact force is generated, and then operated and controlled to ensure efficiency and profitability results. Surely one can see that the process should impose a powerful big challenge on this powerful small abrasive particle steel:

Size S-660 – 1/16 Size S-70 – about 1/100 inch The impact energy of the grinding steel is squared by its mass and the speed regulated by the kinetic energy equation: KE = 1/2MV2.

The key to understanding the effect on the “mass” factor in the choice of magnitude is that the mass of the sphere varies with the cube of its diameter.

Double shot size builds the mass, or effect control per pellet eight times! Alternately, double shot size lessens the pellets per pound to one-eighth.

How much impact-force is required?

Looking at the opposite aspect, what are the characteristic of the contaminant to be removed? How much impact force is required?

Prior to the approach of metallic abrasives, blast cleaning was finished utilizing sand as the media, i.e., sandblasting. Indeed, even with lightweight sand, the effect was adequate to remove the contaminant and produce an engraving wrap up. An estimate for the measure, at a similar speed, steel abrasive has 2-2.5 times more impact force than sand, and when steel shot or grit is bigger than sand, its impact force would be greater so cleaning fast and better.

Cost-efficient work-mix

A viable, cost-effective work-mix contains an appropriately adjusted dispersion of extensive, medium, and small particles. The bigger pellets, with maximum impacts force, must be sufficient enough to play out the significant task of loosening thick, firmly following contaminants, and still give a worthy complete profile. The small particles give the scope important to the quick evacuation of the lighter contaminants, and to scour and clean rust, etc. in minute pits and cleft that large shot or grit can’t reach.

How little can the abrasive particles be and still aid in cleaning? Maybe this is the best answered by pointing out that shot as little as S70 is powerful in removing tenacious oxide scale from the hot-rolled stainless steel strip.

Out-of-Balance Work Mix

A work-Mix with a prevalence of fines has deficient effect constraint to be powerful (few large pellets to break up thick contaminant). Then again, a work mix with a prevalence of large pellets has a low pellet count results about a wide, open example that requires a great deal more impact time to carry out the job.

Out-of-adjust work-mixes requiring extended blast time, or diminished line speed, as well as re-blast, have serious adverse efforts for product complete, productivity, and working expenses.

Controlling the Work mix

➢Add new abrasive every working movement. Maintain feed hopper at or over 3/4 level constantly

➢Try not to enable abrasive spillage or leakage to accumulate, return to the system daily.

➢Check the work mix size distributions week after week. Suggested: Use the Ervin Spot-Check Gauge, which requires under five minutes to utilize, providing instant feedback indicating whether the work-mix is in balance or not

The Blast stream is on Target or not?

The misdirection of the blast stream, with some abrasion missing work, and more affect the wear parts of the equipment, causes these problems:

➢Incomplete removal of impurities

➢Excessive wear parts

➢Excessive machine downtime

➢Excess use of Abrasive

➢Lower productivity due to extended blast time

What must be perceived is that the unavoidable factor of wear and tear on blast wheel component will in the long run reason a move in the location and concentration of the blast pattern. Exceptional wear tolerance has been built into blast equipment, however when wear goes beyond the tolerance, components can never again perform appropriately, and the blast pattern strays from the target.

Problems Recognitions:

The key to efficient and cost-effective blast cleaning is the ability to identify problems, how and when they occur. This can be done with fast and simple controls. Education is important to understand the means used and their function; it is to make the main operating data meaningful for the worker.

A solid, basic understanding of the principals involved in the blast cleaning, coupled with discipline in a performance evaluation program (SPC), will make the blast cleaning service department more efficient and effective part of any operation.