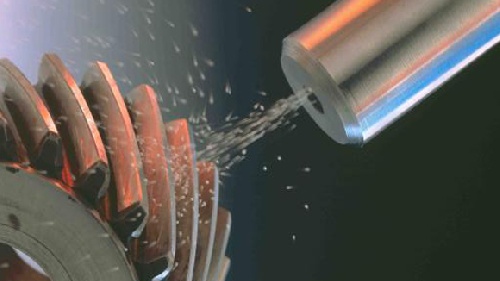

The shot peening-process is based on applying compressive stress in the surface layer of the metal part by shooting of small hard round particles with high velocity against the surface of the part.

Shot pinning is a cold working process in which fine-grained abrasives effect on the surface of metals by playing impact and bombardment. In this process, by hammering the round shot particles at the surface, the surface layer compressed and cracks and defects have been removed. As a result of these stick up, the subsurface stresses reach the yield strength and try to return to their original state. By continuing this compression, the fatigue strength of the surfaces improved.

Shot peening is a type of blast operation with a sufficient size, granulation and hardness and also proportional to the work pieces. In this process, each abrasive grain acts in impact with part surfaces like small hammer and creates a small depression, which finally creates an effective compressive stress with a huge set of these depressions and neutralizes the residual tensile stress of previous processes such as grinding, machining, casting and other metal forming processes.

It’s commonly used to peen aerospace components, automotive suspension springs, power transmission, engine components, mining, oil & gas and many other applications for improving the fatigue life of metal components.

Significant Reasons of shot peening process

- Increasing fatigue resistance

- Enables lighter design

- Prevent cracking of materials under high stress

- Improving of erosion characteristics

- Prevention of hydrogen brittleness

- Increasing corrosion resistance

- Lubrication of special parts by creating a suitable surface pattern

Parameters affecting on shot peening

- Shape, Material, hardness and size of the media

- Control process and angle of throwing

- Velocity, intensity and time of peening and sweeping the surface of work pieces

- Material work pieces